WHY SKD

Reduce 30% Logistics Cost, 50% Faster Market Entry

Cost Reduction

Importing products in the form of SKD can reduce product costs by reasonably avoiding tariffs.

Product Localization

Product localization can not only enhance products competitiveness ,but also increase the local market share of the industry.

Policy Subsidy

Electric vehicles are a global trend, so many governments now issue policy subsidies to support the development of the EV chargers industry.

WHY ECAIPOWER

What SKD Service Can We Offer For You

At ECAIPOWER, we specialize in providing customized SKD (Semi-Knocked Down) assembly solutions for electric vehicle (EV) chargers. We ensures that every product meets high-quality standards while supporting the global transition to electric mobility.

It’s a long process to develop a new industry, but we will leverage our existing mature experience & product to help you establish a foothold in your market.

Expertise in Manufacturing

- Strong R&D Capabilities

- Certified Quality Assurance

- Comprehensive Charging Solution

- Professional Technical Support

10+

Years Experience

96+

Implemented Solutions

132+

Exporting Countries

SKD Modularization

How Is The Assembly Process Carried Out?

(7kW AC Charger as an example)

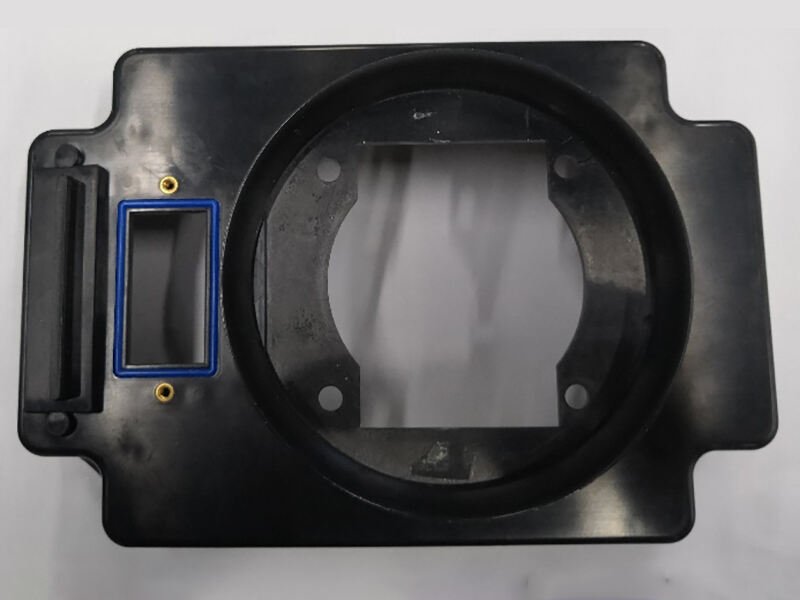

Components Pre-installation

Firstly, install the fan, 4G module, indicator light board, and battery display board.

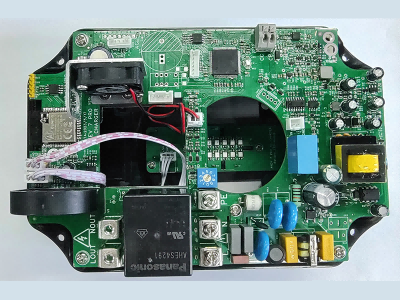

Main Sections Installation

Secondly, install the motherboard, then connect the port cable and install it into the bottom shell.

Final Inspection & Packaging

Finally, the assembled product will undergo a series of tests and aging before being packaged and presented to customers in the most perfect way.

Test Equipment

What Should Be Prepared Before Starting?

Aging Room

High-temperature Aging Rack

Load Bank

Ambient-Temperature Aging Rack

Hear from the Customers

What They Say About Our Product?

Application Scenarios

Where Can The Products Be Applied?

OUR FAQ

Frequently Asked Questions?

SKD means Semi-Knocked Down, which means breaking down the EV charger into semi loose parts for import, which can reduce the import tariffs and shipping cost, but at the same time it also requires the enterprise to have certain assembly and technical capabilities.

The main benefits include reducing tariffs, lowering transportation costs, shortening delivery times, and increasing product market share. In addition, the localization of products also helps create employment opportunities and comply with government regulations regarding electric vehicle infrastructure.

ECAIPOWER will provide customized SKD solutions based on your actual needs, and provide complete technical documentation, core components, and expert guidance to help customers establish local assembly businesses. Our Professional engineer team is committed to ensuring a smooth transition and effective training during the assembly process.

SKD solutions are suitable for our various types of EV chargers, including AC chargers, DC fast chargers, and dedicated charging stations compatible with IEC, SAE, and GB/T standards, ensuring a wide range of customer applications.